Search This Supplers Products:filter making machine

Part II. How are Filters Seamed? What are Seaming Tools?

time2019/08/09

- Filter seaming process

I. Filter Seaming Process

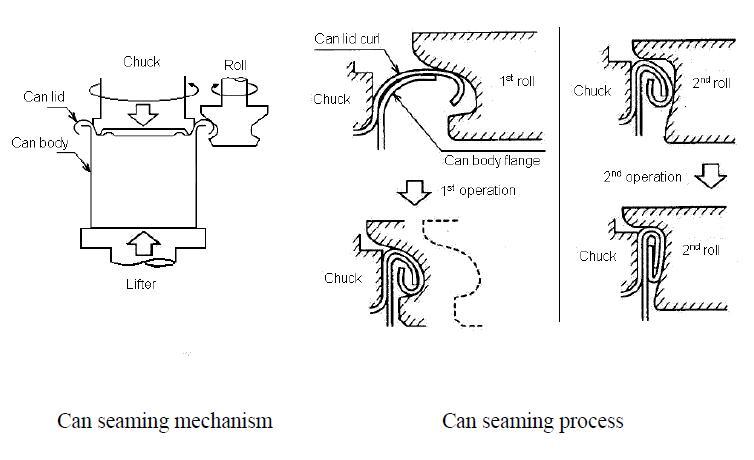

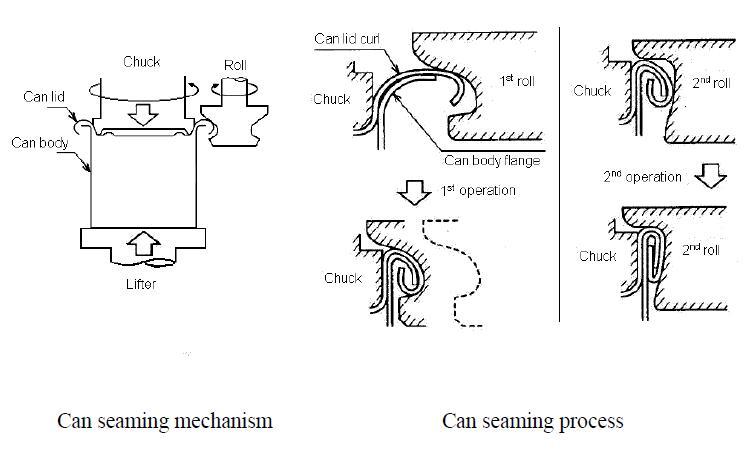

In the can seaming process (Fig. 1), the filter housing and lid are held between chuck and lifter, and then rotated before the lid is pressed against the seaming roll to carry out seaming. There are two types of seaming roll : 1st roll and 2nd roll.

The first roll approaches the filter lid, and rolls up the lid curl and body flange sections of the can before retreating. Next, the second roll approaches to compress the rolled-up sections to end the seaming.

In other words, the 1st roll rolls up the can lid and can body, doing mainly the bending work; while the 2nd roll compresses the rolled-up sections, and mainly does the seaming work.

Fig 1. Filter Seaming mechanism and process

II. How to Calculate the Seam Thickness?

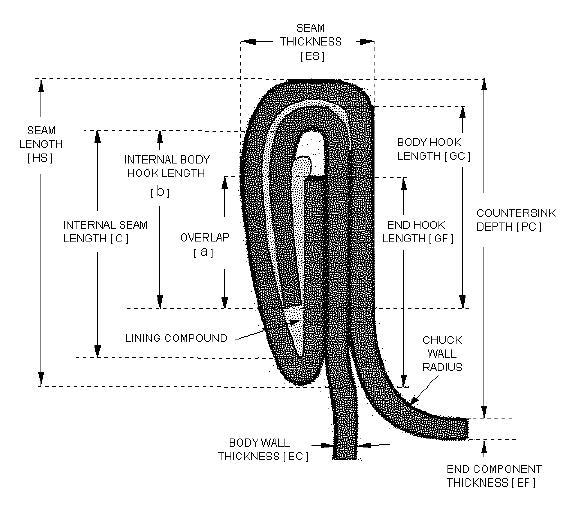

The can seam obtained, double seam (Fig. 2), consist of five thickness of plate interlocked or folded and pressed firmly together, plus a thin layer of sealing compound.Add description

Fig 2. Filter Seaming Dimension

The Formula:

Seam Thickness(ES)=Filter Housing Thickness(EC)*2+Bottom Plate Thickness(EF)*3+Sealing Compound(Glue)*2

ES=EC*2+EF*3+Glue*2

*If glue applicable, count the glue thickness; If no glue, ES=EC*2+EF*3.

Conclusion

There are many factors influence the seaming quality of a filter: chuck, roll, design of seaming machine, accessories quality etc. Choose a reliable suppler with experience is th key to save you from all traps.

We, ZHENGYE Filter Equipment, have been in the filter making machine field since 1993. Filter machine machine is our Advantage product line. From Semi-auto to Full-auto, From car to heavy duty to equipment. We all can handle it with ease.

For more questions, please contact below. Pleasure to help.

__________________________

Miss Alexandra

ZHENGYE Filter Equipment Co., ltd

Web: ..........com

Email: zhengyechina..........com

WhatsApp: +86-156-0665-3505